The growth of our civilization has seen a parallel growth in the food industry. In pre-historic ages humanity was dependent mainly on vegetables, fruits and meat for its daily food intake. However, over the years there has been an increasing demand for processed synthetic foods to cater to the needs of a growing population and to meet scarcities in different regions having harsh climatic conditions.

Processed foods need to have some basic characteristic properties which make them acceptable to the consumer. Some of these features are:

Colour which can be introduced with a blend of natural and artificial colouring agents

Flavours need to be added to make foods appealing or suppress some inherent bad odours

Preservatives are needed to improve the shelf life for long time storage and use

Stabilisers are added to improve their texture. This means modification of the crystalline behaviour and characteristics of the phases of different constituents

Anti- oxidants are added to prevent decay of food by oxidation

Emulsifying agents help in facilitating uniform distribution of fats and oils in aqueous media

Buffering agents control the acidity or pH of the food over storage period

The number of additives added to foods are growing by the day to match consumer tastes and lead to a corresponding increase in market potential.

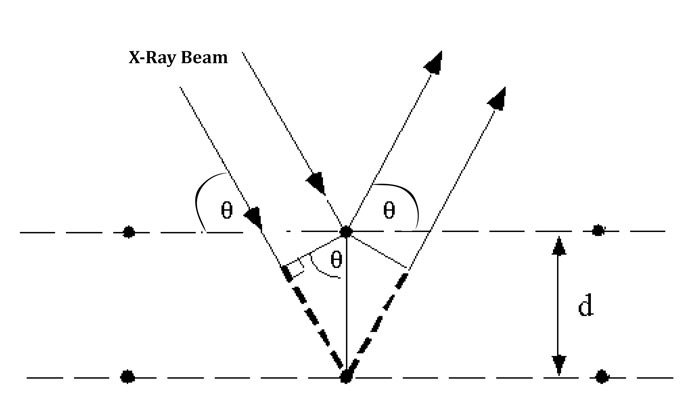

Several analytical techniques are routinely used to monitor the d presence of such food additives in manufacturing processes. The role played by XRD cannot be overlooked. X-ray diffraction provides us information on polymorphism, degree of crystallinity and amorphism. Such parameters help control the texture and stability of foods under different storage conditions.

X-ray diffraction has helped conduct studies on following common food ingredients such as

Starches

Fats

Candies

Starches

X-ray diffraction complements the DSC studies in starch gelatinization in foods. Gelatinization results when starch crystals melt with increasing temperature. It has been observed that the melting temperature increases with the decrease in moisture content. Gelatinization decreases the degree of crystallinity of starch granules and increases the non-crystalline amorphous content. This results in apparent changes in optical and rheological flow properties of foods.

Fats

X-ray diffraction has been extensively used in studying the polymorphism (different molecular packing arrangements in crystals) of fats such as margarines. The three common polymorphs of fats are α, ß and ß’. Packing arrangement in α form is hexagonal, triclinic in ß and orthorhombic in ß’. The ß form is the most stable form whereas α form is the least stable of the three. Polymorphic differences are of significance in food industry as such differences bring about changes in physical properties such as texture. Such inter- conversions can result from transitions from ß’ to the more stable ß form under different processing conditions.

Candies

Candies and chocolates are very popular among children. X-ray diffraction plays a useful role in manufacturing products of consistent quality in terms of sweetness, texture and flavor. Such characteristics depend on the balance between crystalline and amorphous proportions of constituents which can be easily monitored with the help of the X-ray diffraction technique.

The scope of X-ray diffraction in the food industry is increasing as consumers demand consistency of quality and new ingredients are finding their way into new products which are developed at an amazing pace.